Choosing the Right Torque Wrench or Driver for Your Project: A Comprehensive Guide

- Yong Jim

- Feb 19, 2025

- 4 min read

Torque wrenches and drivers are essential tools for any job requiring precise fastener tightening, from assembling furniture to working on critical automotive or aerospace components. Applying the correct torque prevents over-tightening, which can damage fasteners or the materials they're securing, and under-tightening, which can lead to loosening and potential failure. But with so many types and features available, choosing the right torque tool can be daunting. This guide will break down the different types and key considerations, including the increasingly popular battery-powered options, to help you select the perfect torque wrench for your project.

Understanding Torque and Its Importance

Before diving into torque wrench types, let's briefly define torque. Torque is a rotational force that tends to cause rotation. It's measured in units like Newton-meters (Nm) or foot-pounds (ft-lb). Every fastener has a specified torque value, and using a torque wrench ensures you achieve that precise level of tightness.

Types of Torque Wrenches:

Click-Type Torque Wrenches: These are the most common type and are known for their ease of use. You set the desired torque value on the handle, and when you reach that value while tightening, the wrench emits an audible "click" and a slight feel, indicating you've achieved the correct torque. They are versatile and suitable for a wide range of applications.

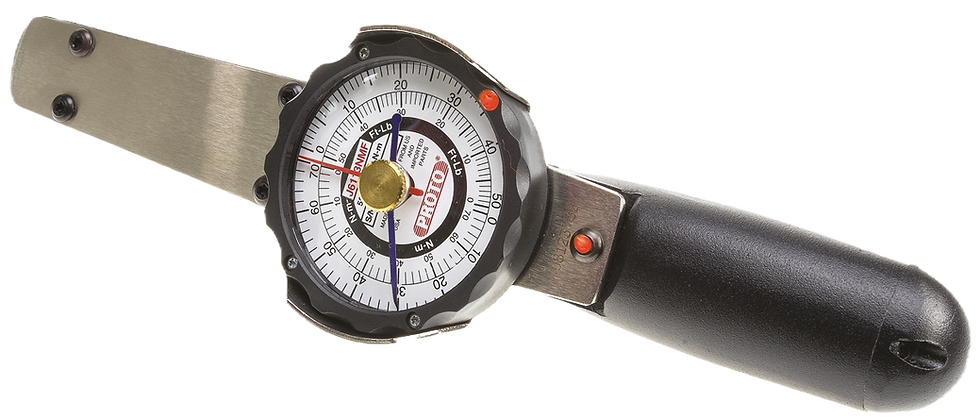

Dial-Type Torque Wrenches: These wrenches feature a dial gauge that displays the applied torque. They offer high accuracy and are often used in situations where precise torque is crucial. Like beam-type wrenches, they require a visual reading of the dial

Digital Torque Wrenches: These are the most advanced type of manual torque wrench. They feature a digital display that shows the torque value, and some even offer features like programmable torque settings, data logging, and audible alarms. Digital torque wrenches are highly accurate and are often used in critical applications where precise torque is paramount.

Digital Torque Wrench

Battery-Powered Torque Wrenches: Also known as electric torque wrenches, these offer a significant step up in efficiency and often incorporate the advanced features of digital wrenches. They use a motor to apply torque, allowing for faster tightening and reduced operator fatigue, especially in high-volume applications. Many battery-powered wrenches feature:

Battery Torque Drivers Increased Speed: Significantly faster tightening than manual wrenches.

Enhanced Accuracy: Precise torque control, often with feedback mechanisms to ensure accuracy.

Data Recording: The ability to log torque data for quality control and traceability.

Programmable Settings: Store multiple torque settings for different applications.

Ergonomics: Reduced strain on the operator, especially in repetitive tasks.

Pneumatic Torque Guns (Air-Powered): These are powerful tools that use compressed air to deliver high torque quickly and efficiently. They are ideal for heavy-duty applications, such as construction, heavy machinery maintenance, and industrial assembly. Pneumatic torque guns offer:

Pneumatic Torque Drivers High Torque Output: Capable of generating very high torque for large fasteners.

Fast Operation: Rapid tightening and loosening of nuts and bolts.

Durability: Built to withstand harsh environments and heavy use.

Reduced Operator Fatigue: Air power assists in tightening, reducing strain. However, they can be heavier than other options.

Requires Air Compressor: Needs a compressed air source to operate.

Can be Less Precise: While some models offer torque control, pneumatic guns are generally less precise than other torque wrench types, particularly for very precise low-torque applications. They are more about speed and power.

Key Features to Consider (Including Battery-Powered):

Torque Range: Select a torque wrench with a range that covers the torque specifications of the fasteners you'll be working with. Don't choose a wrench with a range too narrow or too broad.

Drive Size: The drive size (e.g., 1/4", 3/8", 1/2") refers to the square drive that connects to the socket. Choose a drive size that matches your sockets.

Accuracy: Torque wrenches have a specified accuracy rating (e.g., +/- 4%). Choose a wrench with an accuracy that meets the requirements of your application. Battery-powered wrenches often boast very high accuracy.

Handle Design/Ergonomics: A comfortable and ergonomic handle is important, especially when working on projects that require repetitive tightening. Battery-powered wrenches often have ergonomic designs to minimize fatigue.

Build Quality: Look for a torque wrench made from durable materials that can withstand regular use.

Battery Life (for battery-powered): Consider the battery life and charging time if you're choosing a battery-powered torque wrench. Look for models with long runtimes and fast charging capabilities.

Data Logging Capabilities (for battery-powered/digital): If data recording is important for your application, ensure the wrench has this feature.

Programmable Settings (for battery-powered/digital): This can save time and improve consistency in repetitive tasks.

Choosing the Right Torque Wrench for Your Project:

DIY/Home Use: For general home repairs, furniture assembly, and occasional automotive work, a click-type torque wrench with a suitable torque range and drive size is usually sufficient.

Automotive/Mechanical Work: For more demanding automotive or mechanical work, consider a click-type, digital, or even a battery-powered torque wrench, especially if speed and data logging are important.

Aerospace/Critical Applications: For aerospace, manufacturing, or other critical applications where precise torque, data recording, and speed are essential, a digital or battery-powered torque wrench with advanced features is often required. Battery-powered options are becoming increasingly common in these sectors due to their combination of speed, accuracy, and data capture.

Maintenance and Calibration:

To ensure your torque wrench maintains its accuracy, it's essential to calibrate it regularly. The frequency of calibration depends on the usage and the manufacturer's recommendations. Store your torque wrench in a safe place to prevent damage. For battery-powered tools, also follow the manufacturer's recommendations for battery care and storage.

All tools from Toollang can be calibrated to ISO 17025 so the tools are ready to use out of the box. We provide door to door periodic calibration services. Contact us for more info.

Conclusion:

Choosing the right torque wrench is crucial for ensuring proper fastener tightening and preventing costly mistakes. By understanding the different types of torque wrenches, including the benefits of battery-powered options, and considering the key features discussed in this guide, you can confidently select the perfect tool for your project. Don't hesitate to contact us at toollang.com if you have any further questions or need assistance in choosing the right torque wrench for your needs. We're here to help!

Comments